Andi Moffatt is our vice president of Environmental Services. She has been with WSB since nearly the beginning and has had the opportunity to watch the firm grow throughout the past two decades. In this Q&A, Andi shares her insightful reflections and offers her perspective on the future.

Q: You’ve been with WSB for nearly 23 years. How has the company changed since the early days?

A: Well, we all used to fit in the same room for a meeting! We’ve grown so rapidly. During our first hiring boom, I remember looking around and thinking there were so many new faces. Something that I realize now, but maybe didn’t know back then, was that every time we had this influx of significant growth, the leaders acted. These seasons of growth spurred positive changes for our firm – like the WSB Way. I saw this again in our rebranding process, where we updated our values, but still stayed true to who we were. Our growth has positively forced us to take an introspective look at ourselves.

Q: What has been one of your favorite memories in your tenure at WSB?

A: I can’t just pick one. I have two – one lighthearted and one serious where I truly learned the impact of the work we did. For the fun one, WSB’s original running club signed up for the Reindeer Run around Lake Harriet. When race day came, Pete Willenbring, one of the founders of WSB, was Santa and a group of us were his reindeer. We had to run and carry a very heavy wooden sleigh around the lake. The sleigh wasn’t very light or streamlined for being designed by an engineer!

On a more serious note, the I-35W bridge collapse and what it meant for infrastructure throughout the nation was a touchstone moment. We were all hands-on deck until that project was completed, with staff being on the project 24/7. If you weren’t out in the field on that project, you were back in the office holding down the fort. It’s moments like these that show who we are as a firm – a group of people who will pull together when faced with a challenge.

Q: You lead our firm’s environmental services – what about this work excites you and keeps you coming through the door every day?

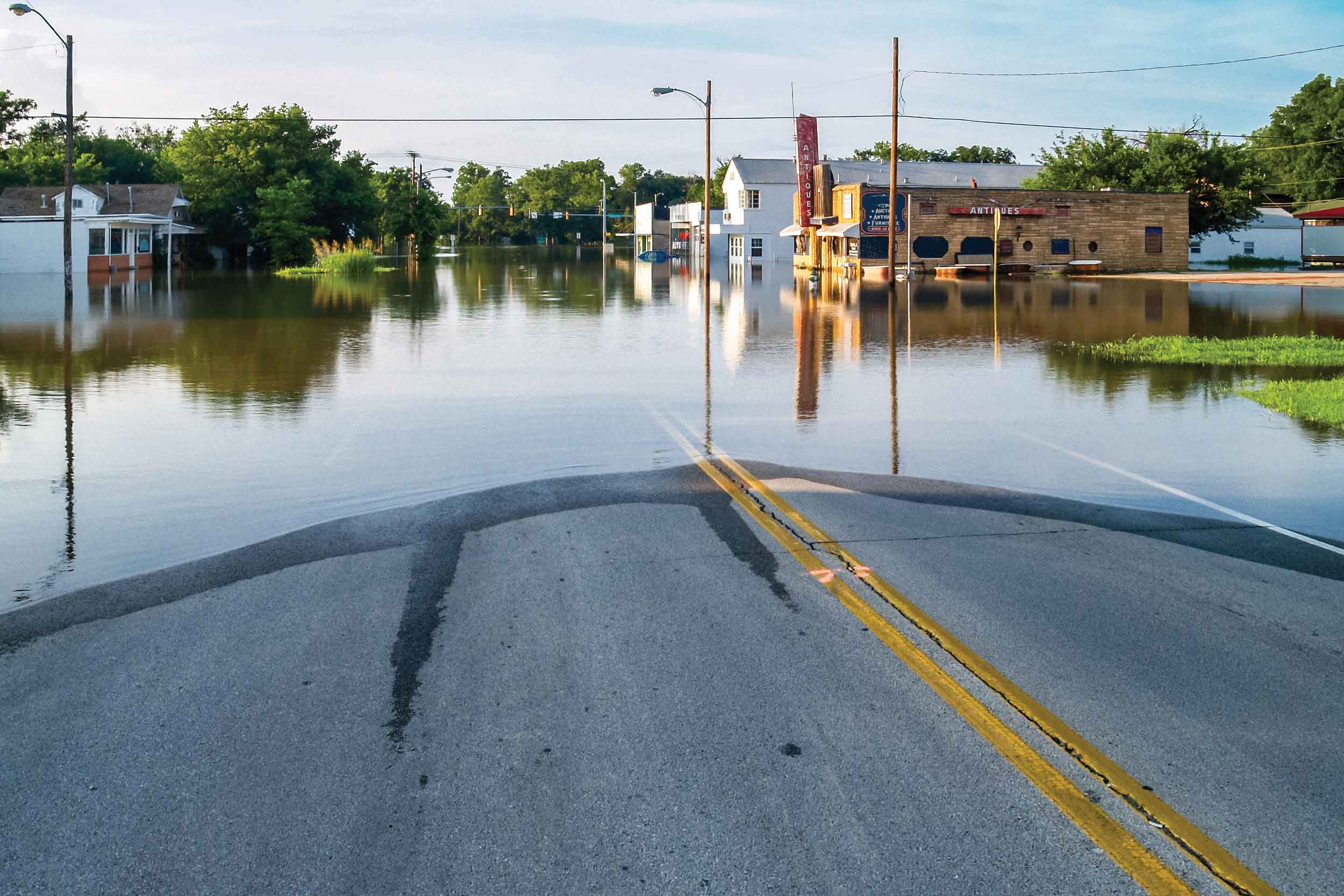

A: I love that we are here to help our clients and communities solve complicated issues. Whether it’s cleaning up a contaminated redevelopment site, solving a flooding problem as we manage significant rain events, or restoring a trout stream to its original state – we’re working with our clients and partners to solve these complicated problems and it’s very fulfilling.

Q: We’re very client-focused at WSB, but we’re also very staff focused. Why do you think this is important?

A: At our core, we were founded to be a company that can be better. If I look back to how we’ve grown, we’re still in many ways living this belief. It’s how we show our authenticity – in the way we treat each other, treat our clients, and the way we do our work. We hire authentic, driven and collaborative staff to continue to drive this mission forward.

Q: In your opinion, what is one of the biggest disruptors on the horizon for our industry?

A: This one was tough for me to answer, but I think it will be about adjusting our approaches for some of the big infrastructure issues that are on the horizon. We’ve experienced more 100-year rain events, more flooding, and more invasive species infiltrating our waterways. Some of the tried and true techniques that we use to solve infrastructure issues aren’t going to be relevant in the future. It’s going to take some creativity and innovation to determine the best approach and what’s going to make the most sense for the environment that we’re living in. The future is unpredictable, but it’s important to start having these conversations now.

Q: How do you position your teams to be at the forefront of some of these disruptors?

A: I think fostering an atmosphere where questions and creativity is encouraged is important. Giving space to ask questions and creating a safe environment where it’s okay to fail helps us to create resiliency. Resiliency is going to better position us to tackle these big disruptors. Recently, I asked some of the young professionals we have on staff for some ideas on projects. They had great ideas I had not considered. It’s so important to leverage all the knowledge that’s available throughout our company.

Q: We were founded on the understanding that culture drives results – how do you think that translates to WSB today, nearly 25 years later?

A: Culture truly drives results and if you don’t tend and care for your culture it can change in ways that can hinder your results. When we have discussions at the leadership level it ultimately comes down to deciding what’s best for the staff and company. Businessman Richard Branson said it best, “The way you treat your employees is how they will treat your customers.”

Q: What do you wish you could tell your younger self when you first started your career?

A: I’d tell my younger self to soak it all up – soak up every opportunity and know that mistakes are okay and inevitable. I remember being so worried about messing up to the point that I wouldn’t take any chances. It’s okay to make mistakes if you own it and you learn from it. I would also tell myself not to feel intimidated by upper management. At the end of the day, we’re all just people.

Q: You’re seen as a mentor to many in WSB – why is mentorship important?

A: I just did an informational interview with a young gentleman who is currently in college. He was so thankful for having an opportunity to ask career questions. He asked how he could thank me, and I told him to pay it forward. When he’s been in his career for 20 years, take the time to sit down with someone on the cusp of their career and answer their questions. I think no matter where we are in our careers, we all still need guidance. Connecting with a mentee helps me learn and be better in my career too. It’s hard to know what’s going on with your team unless you’re really connecting with them.

Q: What does WSB look like in 5 years? 10 years?

A: We look like change. That’s what we’ve always focused on. We will continue to focus on our staff because that’s the core of who we are, and we want WSB to be a great place for everyone who works here. We’re always reaching, striving and changing. In five years or ten years, we’re still changing and innovating and it’s exciting to think about.