December 18, 2023

By Behnaz Beladi, Director of Renewable Energy, WSB

Exploring energy resources beyond fossil fuels.

It is no secret that our future is focused on resiliency, and many communities are shifting toward utilizing renewable energy components. Renewable natural gas, utility scale solar fields, community solar gardens and wind farms all help power communities throughout the U.S.

WSB supports communities from coast to coast and collaborates with diverse clients such a owners, developers and large energy contractors. The scope and scale of our renewable work includes a broad geography of clients and projects.

Renewable energy powers a substantial number of homes, and in a sustainable way. Having energy sources that are replenished by nature and produce little to no greenhouse gases or pollutants into the air is a big step toward living in a more resilient, net zero environment. One Megawatt (MW) of renewable energy can power up to 170 homes. The ability to offer this coverage is an advantage as we push toward a more sustainable future.

Renewable Natural Gas

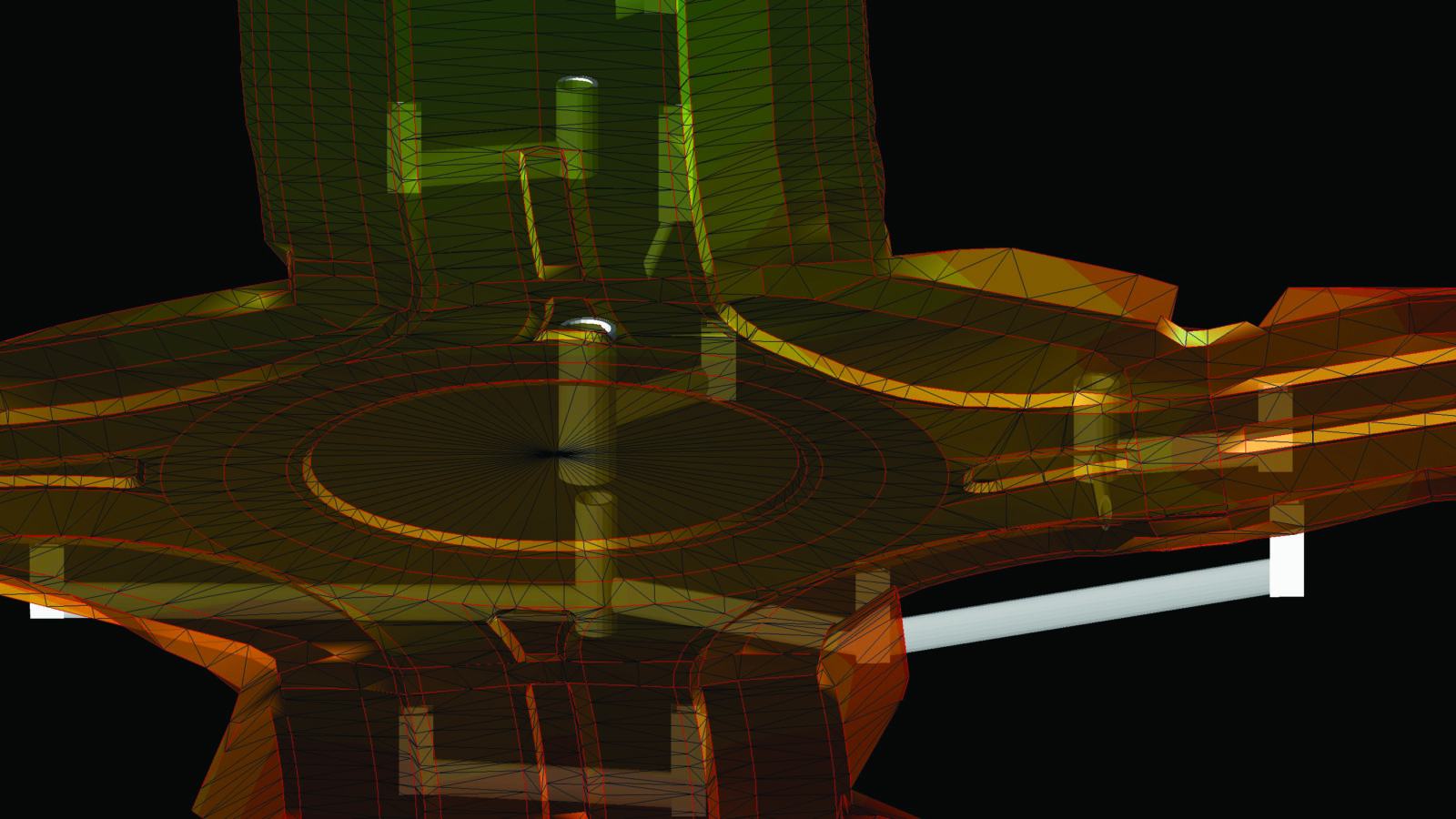

Landfills, hog farm manure and more all are sources of methane. Through organic material decomposing, these items produce a gas that, when handled properly create a promising natural gas. Through a digester, a wastewater treatment plant, impurities can be extracted from the gas and turned into the renewable natural gas that is piped into our houses for daily functions such as heating the stove or furnace. WSB supports these projects in a variety of ways including helping clients get permits from the Public Utilities Commission, surveying, land acquisition and construction staking. The Environmental Protection Agency (EPA) estimates the potential for 8,241 livestock biogas systems that could generate over 13 million MW hours of energy yearly.

Utility Scale Solar

Typically hired by a large Engineering, Procurement and Construction (EPC) firm, we support utility scale solar projects to provide solar design. These large solar fields vary from 3,000-5,000 acres, equivalent to about 30 miles of roadway and millions of miles of cubic dirt moved for the solar panels to be installed. With renewable energy on this large of a scale, these is the potential to power 250 MW, or about 50,000 homes. In addition to design, WSB provides a design-build partnership – offering construction support and the automation of construction when working on these projects.

Community Solar Gardens

Like utility scale solar, community solar gardens are a way to meet energy needs and are the best fit for smaller projects or clients. Community solar gardens are behind the meter projects constructed for midsized developers such as nonprofits, community-based organizations, tribes or private owners. In this instance, a community comes together to get solar energy rather than energy from the grid. Instead of using a large solar field, like utility scale solar, community solar gardens utilize small amounts of land and roof space to generate the power for the community. Depending on the state and jurisdiction, these projects often range in size and in how many Megawatts they supply, but typically range from one to ten megawatts.

Wind Farms

Wind turbines are very similar to solar fields in how they produce energy, but there are some differences. A key difference between the improved efficiency of wind farms and solar panels is that wind turbines can provide energy at all hours of the day. Wind farms also allow producers to maintain their land and continue to use it for its original use. By utilizing wind turbines farmers can continue to operate on the land – a luxury that does not exist on solar sites. A single wind turbine can produce between 2-3 MW, providing between 340-510 homes with energy. From surveys, site assessments and permitting to design, WSB can support your wind energy needs.

Renewable natural gas, utility scale solar fields, community solar gardens and wind farms all support communities across the country with sustainability at the forefront. As society continues to shift toward a future of resiliency and explore resources beyond traditional fossil fuels, living in a net zero environment becomes more attainable. WSB is proud to offer a variety of services and many subject matter experts to assist in the transition and better your community.

Behnaz is a lead solar engineer and manager specializing in utility scale, commercial and residential solar design. She is mindful of and knowledgeable about all local state and federal environmental rules and regulations and adept at explaining complex technical engineering concepts clearly and accessibly to wide variety of professional and nonprofessional audiences.

[email protected] | 612.468.8423